Strippers and Degassers

Air / Steam Strippers

Strippers are used to remove dissolved gasses like Sulphide and ammonia in wastewater and hydrocarbon/ solvent contaminated in wastewater.

Air strippers are packed bed or sieve tray towers with air used as a medium for stripping the dissolved gas stream.

Steam stripping for wastewater purification is a distillation process where light volatile organics/ sour water (H2O and NH3) are removed from water (a heavier component). The volatile organics/ ammonia present in the feed stream to these types of columns are usually in low concentrations in comparison to the water phase.

Steam stripping takes place at high temperatures that are usually very close to the boiling point of water.

The removal of volatile organics is a strong function of temperature. Steam stripping allows for the removal of heavy soluble organics that other stripping techniques will not remove (Air, etc).

Paramount Limited designs and installs Air Strippers and Steam strippers.

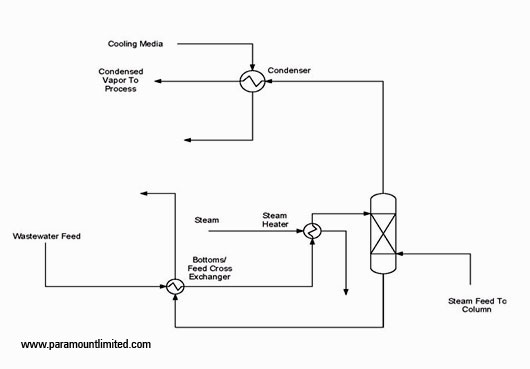

The typical arrangement of a steam-stripping column is a column where the liquid feed is introduced at the top of the column while steam is introduced at the bottom of the column. The wastewater feed stream is heated and put in contact with steam in a packed or trayed tower.

The combined effects of the steam and heat cause organic material/ Hydrogen Sulphide to transfer from the liquid phase to the vapor phase. The steam-stripping tower utilizes trays or packing internals to facilitate contact between the contaminated water stream and the steam stream. The volatile organic material/ ammonia is then carried out with the vapor. As contacting proceeds down the column, the wastewater becomes leaner with organic material/ ammonia while the vapor phase becomes more enriched with organic material/ ammonia as it travels up the column.

In solvent/ hydro carbon strippers, the overhead organic vapor that comes off the top of the column is condensed and recovered. The recovered hydrocarbons are either treated with an incinerator or recycled back into the process. The treated water that comes off the bottom of the column can be recycled back into the plant’s water system. Steam stripping in wastewater service offers high VOC recovery (Greater than 99%). The treated water at the bottom of the column has very low contaminated concentrations.

In ammonia strippers, the overhead ammonia vapor that comes off the top of the column is condensed and recovered. The treated water that comes off the bottom of the column can be recycled back into the plant’s water system. Ammonia strippers are largely installed in a Nitrogen based fertilizer manufacturing (like urea, diammonium phosphate, etc) industry. The recovered ammonium hydroxide can be recycled back into the process.

Typical Steam Stripper applications are:

• Solvent recovery or removal (tetrahydrofuran, hexane, heptane)

• Benzene removal from wastewaters

• Sour water (H2S and NH3) stripping

• Phenol recovery

• Acetone removal/recovery from wastewaters

• Alcohol (ethanol, propanol, IPA, butanol) removal from water

• Oxygenate (MTBE, MEK) removal/recovery

• Removal of chloroform, bromoform and other halogenated organics from water

• Removal of various organics from quench waters

• Concentration and organics recovery from leachates

A typical representation of Steam Stripper is shown in the figure.

Air strippers in combination with caustic Wet scrubbers are used for effluent having Sulphide dissolved water. Air stripper tower utilizes trays or packing internals to facilitate contact between the contaminated water stream and the air stream. The Sulphide is then carried out with the vapor. The treated water at the bottom of the column has very low contaminated concentrations.

In sulphide strippers, the overhead Hydrogen Sulphide vapours that come off the top of the column is passed through a counter current sieve tray/ packed bed or cross flow type caustic Wet scrubber to scrub the Sulphide gas from the gas stream. The treated water that comes off the bottom of the steam stripper column can be recycled back into the plant’s water system. The bleed from the caustic Wet scrubber is treated separately. Paramount also offers Double Alkali Recovery System to recover caustic soda from the caustic Wet scrubber bleed for reuse and economize the caustic soda consumption.

Steam Stripper will be more economical if air post treatment is required.

Degasser Tower

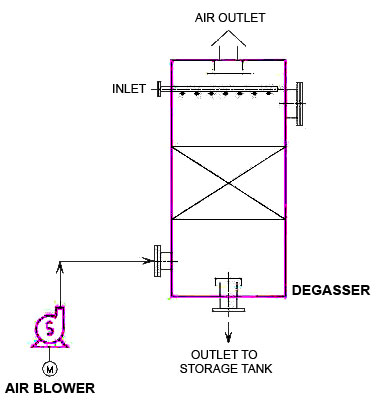

Degasser in water treatment is referred to De-carbonator where the primary importance is to remove Carbon Dioxide from the water.

Paramount Limited design, manufactures & develops Degasser for removal of alkalinity from feed water to boilers, as a de alkalize unit, and for post RO for removal of Carbon Dioxide. Paramount Limited can deliver these as a package unit tailor made for any Capacity. The largest delivered so far by Paramount has a Capacity of 750 m3/hr.

Paramount design, manufactures & develops Degasser for removal of alkalinity from feed water to boilers, as a de alkalize unit, and for post RO for removal of Carbon Dioxide.Paramount can deliver these as a package unit tailor made for any Capacity. The largest delivered so far by Paramount has a Capacity of 750 m3/hr.

Degasser in water treatment is referred to Decarbonator where the primary importance is to remove Carbon Dioxide from the water. They play an important role when Alkalinity is present in water. Water containing alkalinity causes deposits and blocks the tubes in the boiler.

It is placed after the Cation exchanger to mechanically remove the Carbon Dioxide. Water containing Bicarbonates when passed through the Cation Exchanger is converted to Carbonic Acid. The Carbonic Acid easily breaks into Water and Carbon Dioxide.

HCO3 = H2O + CO2

This CO2 can be mechanically removed by the Degasser by blowing air counter current to the water flow.

Degasser is a simple arrangement with a packed tower having plastic rachig rings / pall rings, which enables the water flowing down breaks into droplets due to the high surface area of the packing and releases the carbon dioxide. The air blown from the bottom carries away the carbon dioxide through the vent on the top of the degasser.

The Degassed water is stored below in the tank for further use.

Why the Degasser ?

Degassed helps remove the Carbon Dioxide from the water which otherwise gets into the Anion exchanger and loads the exchanger. The Carbon Dioxide is considerable and the quantity of the resins increases and hence the capital cost and also the recurring cost of the Alkali for regeneration.

With the Degasser the size of Anion comes down.

The Degasser are installed after the RO to remove the Carbon Dioxide generated before the is taken for further treatment.

Contact Us At

Address

Paramount Limited, Paramount Complex, Near Natubhai Circle, Race Course, Vadodara, Gujarat - 390007

Phone Number

Vadodara: +91-0265-2397111

+91-0265-6603700

New Delhi: +91-11-26186525, 26186369

Mumbai: +91-22-24078105

Email Address

Vadodara: sales@paramountlimited.com

New Delhi: delhi@paramountlimited.com

Mumbai: mumbai@paramountlimited.com